Rope Technology

General

Information

Handling and Storage of ropes

➜ Handling of reels

The reels should be transported by using suitable lifting gear, like lifting ropes, slings, chains or crossbeams respectively fork lifts. For the transport of light rope rings, textiles lifting belts or slings are suitable. Please avoid touching the rope during the reel handling. This can already lead to mechanical damages of the rope

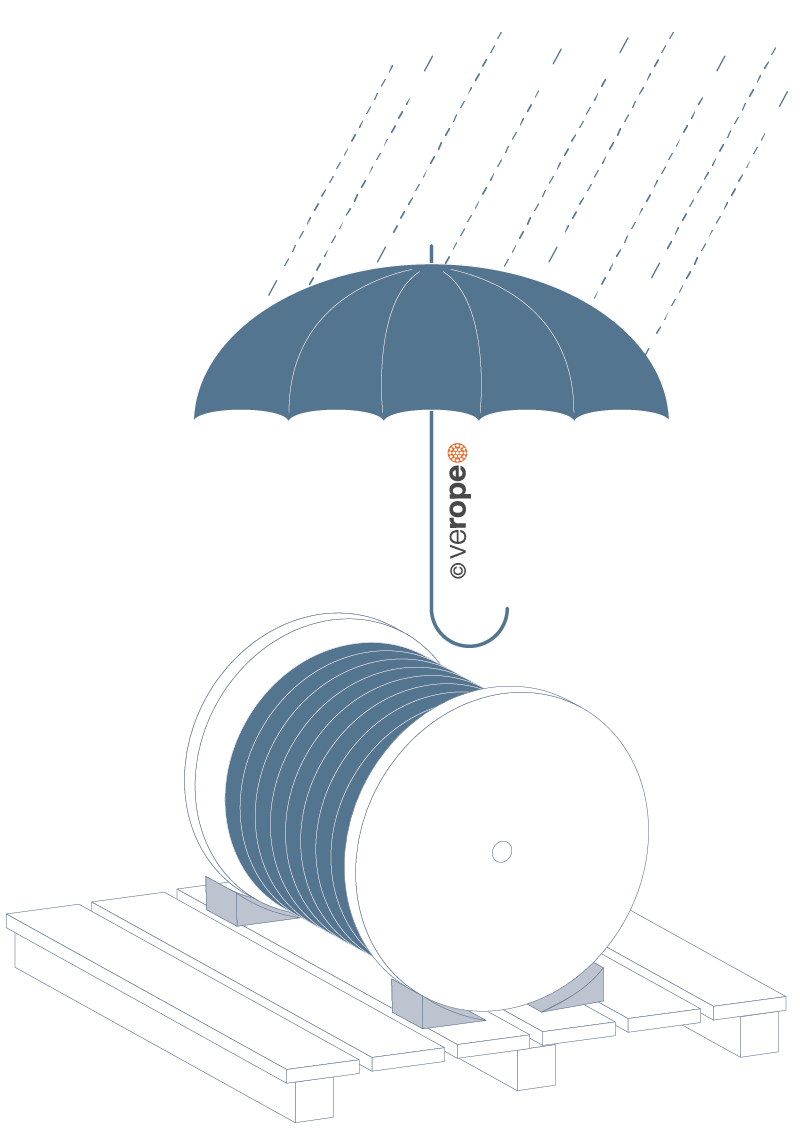

➜ Rope Storage

Wire ropes are to be protected against dirt and humidity during storage. Ideally they are stored in suitable halls. During storage the reels are to be secured against rolling away. During storage outside, they are to be protected against humidity and other environmental factors in the best possible way. Please note that the cover of the reels should ensure that the rope under it is always ventilated enough in order to avoid corrosion due to condensation. Please put the rope also not directly on the ground, but better on a palette or squared timbers. Ungalvanized ropes should not be stored outside for a longer time. With unfavorable storage terms, like for example too high temperatures, it can be necessary that the ropes have to be re-lubricated before use.

Installation of wire ropes

The installation of a rope should always be prepared in the best possible way.

➜ Control of the new rope

The new rope is to be controlled with regard to the construction and the lay direction of the rope, moreover the effective rope diameter is to be measured. This information should also be compared with the delivery documents.

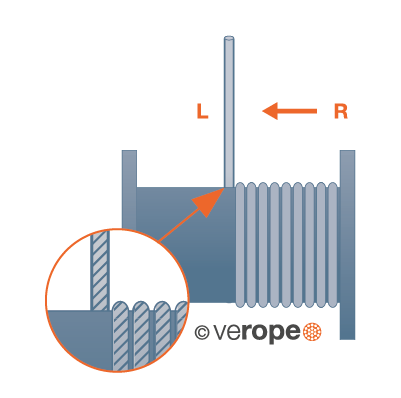

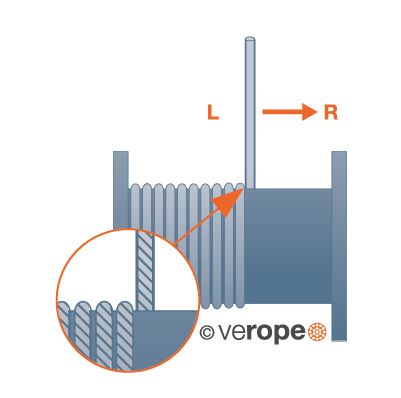

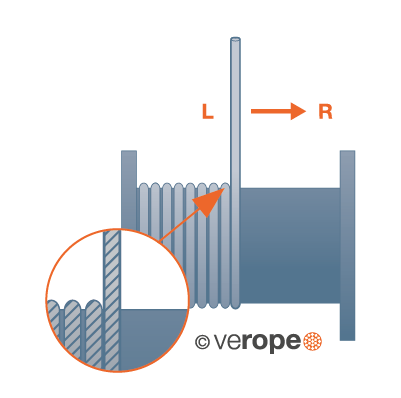

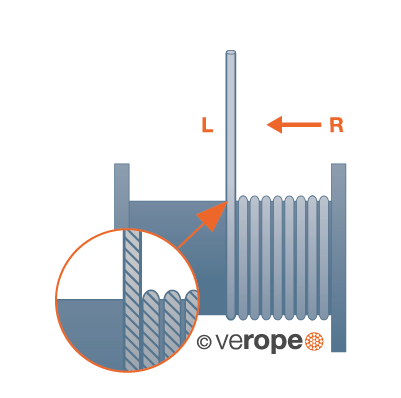

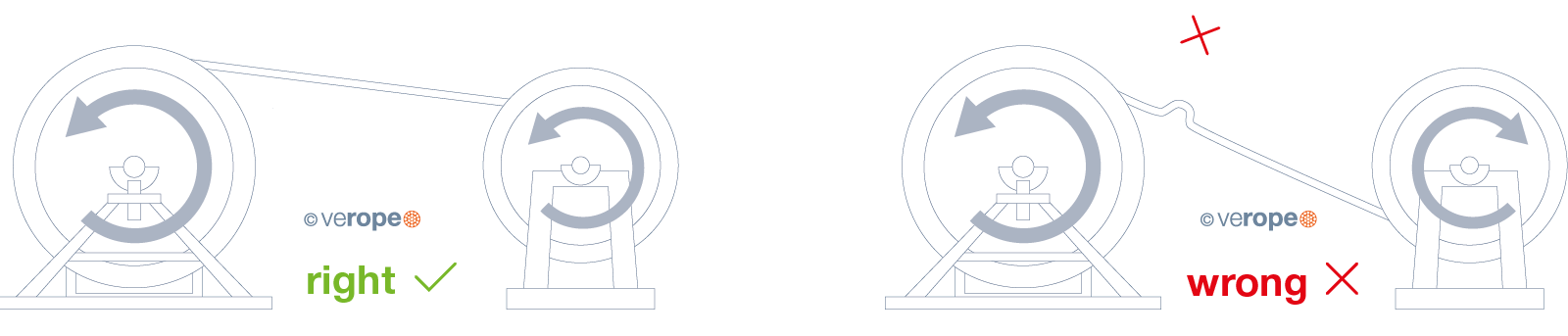

The following graphic shows the correct allocation of the lay type of the rope, right hand or left hand lay, to the present drum, which winds the rope from above (overwind) or from underneath (underwind). Drums can be divided into right hand and left hand lay. The proven rule for the right rope choice says, that a right hand lay rope should be used on a left hand lay drum and vice versa. This is valid for all single-layer drums. We recommend following this rule also for multi-layer drums.

Case A: uwinding direction is from right to left. Left hand lay drums require right hand lay ropes

Case B: uwinding direction is from left to right. Right hand lay drums require a left hand lay ropes

Case C: overwind: winding direction is from left to right. Left hand lay drums require right hand lay ropes

Case D: overwind: winding direction is from right to left. Right hand lay drums require left hand lay ropes

➜ Inspection of sheave grooves (visual and dimensionally)

After the discard of the old rope, all dimensions of the grooves have to be inspected, the grooves of the sheaves as well as the grooves of the drums. The inspections of the dimensions can be done with suitable groove gauges. Damaged or sluggish sheaves should always be exchanged or reworked.

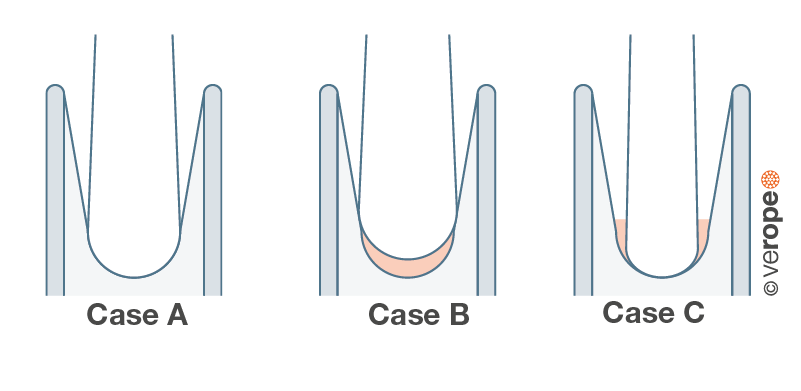

Possible outcomes of the groove inspection

Case A: The groove is ok.

Case B: The dimension of the groove is smaller than required by the standard. In this case the rope should not be installed because it would be clammed and therefore damaged in the groove. Unavoidable damages of the rope structure would be the consequence.

Case C: Although too big sheave grooves reduce the lifetime of a rope, it is practically not that relevant, so first no action has to be taken.

➜ Rope Installation Process

The rope installation has to be done very carefully and always through well trained and experienced staff. Please ensure you observe the following points:

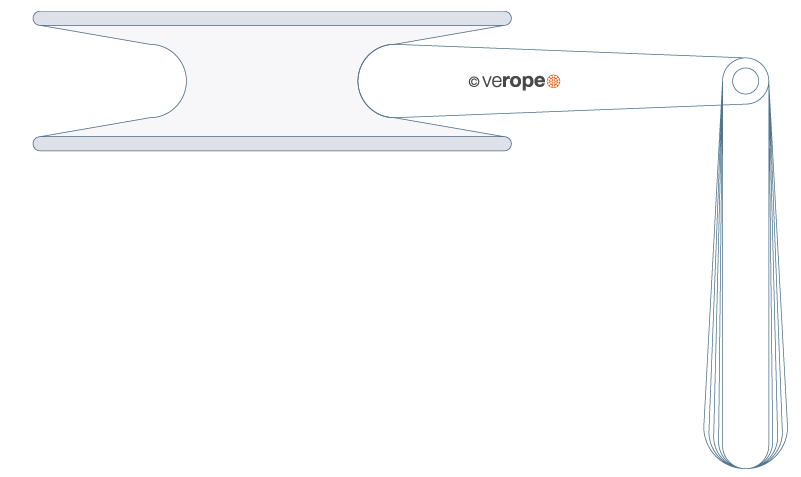

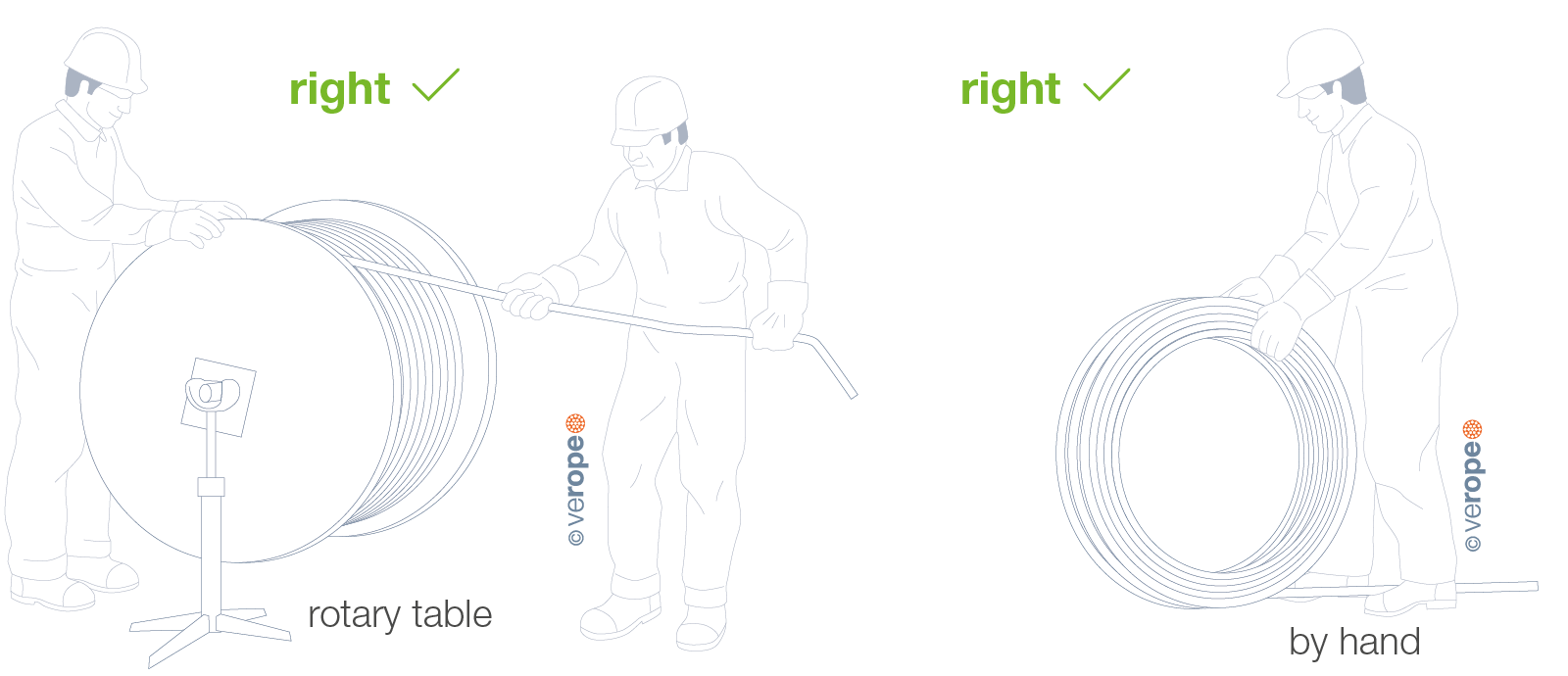

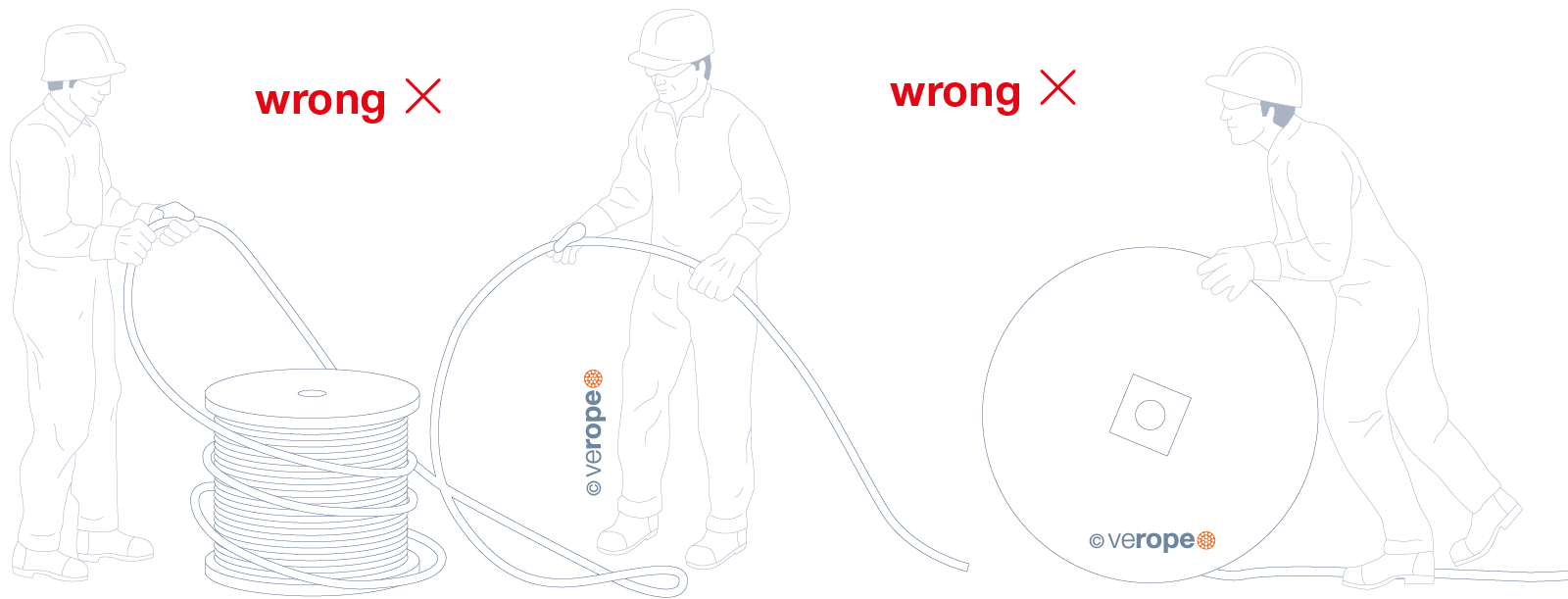

1. While ropes that are delivered on a ring are easily to be laid out, ropes that are wounded on drums have to go over suitable unwinding devices like a rotary table or a reeler.

2. Never pull the rope off the ring or the reel.

This introduces twist into the rope.

3. At some rope installations the insertion of the new rope takes place with the help of the old rope. In particular with the change of rotation-resistant hoist ropes the connection between the two ropes should be chosen in such a way, that the twist that may be in the old rope couldn’t be transferred in the new rope. This can be reached for example by connecting the two ropes over a swivel.

4. Note the winding direction! Please position the delivered reel in such a way, that the winding direction of the rope remains the same. Avoid opposing winding directions with reverse bending during the rope installation.

5. Please check the complete reeving area before starting the winding process in order to make sure that the rope was reeved correct during the installation process and is not let over any edges.

6. Wind and unwind the rope always in a controlled way. We recommend that a person should control the unwinding process of the delivered reel that has speech contact with the crane operator, in order to be able to stop the installation process in case of disturbances at any time.

7. Dismantling of the rope end from the delivered reel. Please interrupt the installation process, when on the delivered reel there are about 5 winds left on the first winding layer in order to dismantle the end fitting that may lay inside the reel respectively the end of the rope. Continue afterwards at a very low winding speed and stop shortly before the endpoint. Stop the installation process and dismantle the end fitting or the rope end.

➜ Initial operation after the installation process

Once the installation process is completed, we recommend a complete reeving of the rope one time. The whole rope length should be moved under low load over all sheaves. This ensures that the rope elements settle within the rope structure. We ask you to repeat this process several times so that the rope is optimally prepared for the application.

With multi-layer spooling the rope is to be winded under preliminary tension, which is explained in the following.

➜ Rope installation with multi-layer spooling

The installation of a rope on a multi-layer drum is particularly challenging! With very big rope length or with an initial installation the whole installation process should be planned thoroughly. This is also valid if the rope lengths are to be put on the crane drum, of which it is known, that after the rope installation an anew winding and unwinding is not possible because of the temporary crane configuration – please see also “initial operation”.

The delivered reel should always be braked if possible. The braking power is to chosen in such a way that the rope winding on the delivered reel will not be destroyed. The generated brake tension makes the winding onto the crane drum much easier. But it usually does not reach the preliminary tension for multi-layer spooling, which is considered necessary. Please see following explanation.

If there are no tools to generate braking force available, the rope should be put on the crane with as little load as possible. The braking power may on no account be generated by clmaping the rope, because this can lead to heavy rope damages already within the installation process.

➜ Importance of preliminary tension of ropes with multi-layer spooling

At multi-layer spooling the preliminary tension of the rope is the essential condition for a correct spooling behavior and the minimization of wear of the rope in the lower, by pressure strongly loaded, winding layers.

Practical experiences have shown that a preliminary tension of the rope of about 10% of the nominal rope pull has a sustainable positive impact. If this preliminary rope tension is not possible due to the rope lengths and/or the crane configuration, then also a lower preliminary tension is also helpful, although not as effective as the 10%.

Signs for insufficient or missing preliminary tension of the rope are winding disturbances which are caused by gap formation in the ropes which are moving under the winding layers due to the load pressure. If this condition is not corrected the cutting of the rope lines may occur and therefore heavily damaging the rope until reaching the discard criteria.

Therefore please renew the preliminary rope tension regularly, at the latest when recognizable winding disturbances occur, over the whole rope length.

Through this the rope lifetime is extended sustainably.

In the multi-layer spooling special wire ropes work, especially rotation-resistant hoist ropes, most economically if the installed rope length on the crane is used regularly.

Should certain rope areas not be used regularly because of the working job or the crane configuration, the application of an adapted rope length is recommended in order to avoid possible rope damages.